Low-Cost and High-Performance Carbon Fibers

Presently, the design of composite materials is of the trend of large size, lightweight and reduction of structure weight, which are the keys to the upgrade of composite material products. For designers, the most convenient way is to use carbon fiber materials of high rigidity since such structure is able to achieve the effect of weight reduction within the safety acceptable range and without the need to adjust the composite material manufacturing.

In Japan a study has been made of the requirements for high performance light weight products, over the next 10 years, it has evaluated that the potential markets with the greatest opportunities for the applications of carbon fiber composite materials in the greatest amounts are the automotive market, wind turbine as well as large civil aircraft.

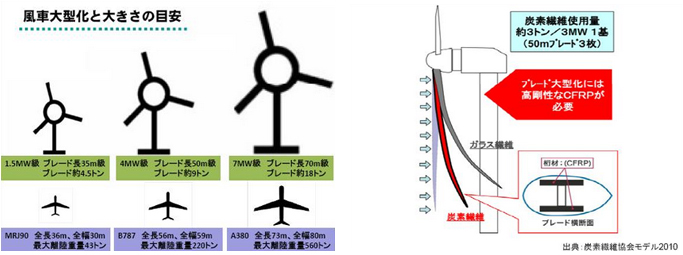

Wind turbine generator blades for 1MW units, 30m in length, and the main bodies, are made of glass fiber. If a 7MW level of large offshore wind turbine generator unit is to be constructed, the length of the blade required reaches 70m long, which is equivalent to length of the wing of an A380 airplane. Since the direction of stress on the blades is specific, the wind turbine generator blades need to use medium and high modulus carbon fibers in order to increase the rigidity, reduce deformation, maintain blade lifetime and to increase the wind conversion efficiency. With the calculation of 3 blades for each generator unit, a 3MW wind turbine generator unit would require 9 tons of carbon fibers.